An extensive list of machine and equipment installed meeting such requirements as cost reduction, short delivery time and many kinds in small quantities production

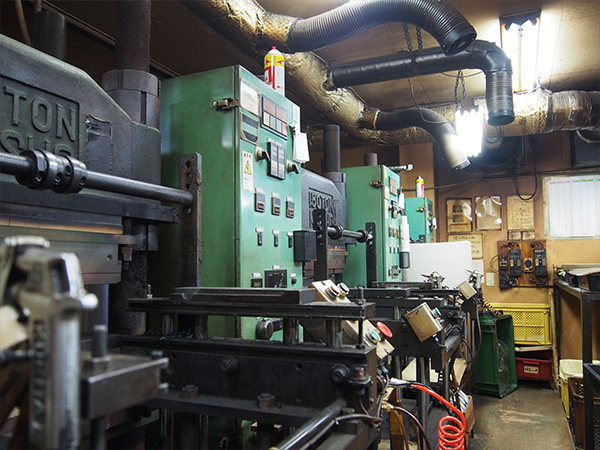

Here is an extensive list of machine and equipment installed at Kuzuhara Gomu, the company providing support for rubber molding and processing from the production preparation stages such as material selection and designing. To enhance our capabilities for our customers, we have a multiple number of equipment with the equivalent machine specifications: e.g. we currently have six units of a large (300 ton vacuum) molding machine against one or two units usually installed by our peer rubber processing company.

Rubber Cutter

The rubber is cut to an appropriate size and weight so that it can be inserted into a mold. The spacing for feeding the rubber into the NC Cutter is programmed to ensure the rubber is cut in consistent dimensions.

| Type | Manufacturer | Model | Cutting Length | No. of Units |

|---|---|---|---|---|

| NC Cutter | Ogino Seisakusho Co., Ltd. | AE1-600 | 1~800mm | 2 |

Rubber Molding Machine

Our molding machines have the production capabilities from 70 ton to 300 ton. Each machine is equipped with a semi-automatic mold disassembly device, permitting a high working efficiency to realize a high precision work. Our vacuum molding machine is so operated as creating vacuum inside the chamber before the mold is set and pressurizing it; this molding process prevents air scratches on the work from occurring. Each molding machine has a program memory function installed, permitting a precise storage of configurations and dimensions of the work for processing. This function of our molding machines is the “secret” in that we can strive for zero defects products.

| Type | Manufacturer | Model | Surface | No. of Units |

|---|---|---|---|---|

| 70-ton Molding Machine | Shinto Metal Industries, Ltd. | WF70 | 450×450 | 1 |

| 70-ton Molding Machine | Meisho-Press, Co. Ltd. | OFB-70 | 450×450 | 1 |

| 100-ton Molding Machine | Meisho-Press, Co. Ltd. | OFB-100 | 510×510 | 6 |

| 150-ton Molding Machine | Meisho-Press, Co. Ltd. | OFB-150 | 510×510 | 6 |

| 150-ton Molding Machine | Iwaki Industry | ISM150 | 510×510 | 1 |

| 150-ton Vacuum Molding Machine | Iwaki Industry | IVM150 | 510×510 | 4 |

| 250-ton Vacuum Molding Machine | Iwaki Industry | VA250 | 510×510 | 2 |

| 300-ton Vacuum Molding Machine | Iwaki Industry | VA300 | 600×600 | 6 |

Rubber Finisher

Liquid nitrogen freezes the work in the chamber of the machine in the range of minus 30℃ to minus 120℃. Under such frozen condition, the media are injected, removing burrs of the work. A conventional deburring is by hands, but our automated process realizes a short processing time of the work at a stable quality, leading to overall cost reduction.

PICK UP!

A must-see information for our peers: we could accept an order of a freezing shot treatment or a freezing tumbler treatment only.

For the benefit of our rubber processing industry for its growth, Kuzuhara Gom provides special services of treatment only in use our equipment below. The price indication of the treatment is JPY1,500 per treatment (plus transportation cost) based on the processing volume of each equipment. No prototype verification cost is charged. A quotation is made upon conditions of prototyping. Please feel free to contacting us about these services for consultation.

| Treatment | Manufacturer | Model | Processing Capacity | No. of Units |

|---|---|---|---|---|

| Freezing Shot | Showa Denko Gas Products Co., Ltd. | ULTRA SHOT NS | 7,000cc | 1 |

| Freezing Tumbler | HISIMURA | NT120 | 60,000cc | 1 |

Heat Treatment Machine (Secondary Vulcanization)

A rubber is heat-treated for long hours at the temperatures between 80℃ and 200℃. The treatment by the machine removes its odor and vaporizes its residue as well. For example, low-molecular siloxane which remains within the rubber component can be removed from the component by such heat treatment of high temperatures for long hours.

| Type | Manufacturer | Model | No. of Units |

|---|---|---|---|

| Thermostatic Chamber | Asahi Kagaku Kogyo Co., Ltd. | S-100 | 1 |

| Thermostatic Chamber | Asahi Kagaku Kogyo Co., Ltd. | CF-60 | 1 |

FANAC ROBODRILL α-D21SiB5

Small size cutting machine with high speed, high precision and high efficiency capabilities. Our new investment enables us to do an in-house die fabrication for prototyping and product development, leading to reduction in both production lead time and cost. Besides, we are capable of making in-house jigs for measurement.

Microscope for measurement

Measurement by hands using a caliper or a dial gauge may result in dispersion of its results caused by an added force by a measurement operator. By using a noncontact measurement method, we can prevent such dispersion and achieve more precise measurement. An image system is mounted on our instrument which can handle the measurement up to the 0.0001 (1/10,000) of a degree.

| Type | Manufacturer | Model | Measurement Range | No. of Units |

|---|---|---|---|---|

| Measuring Instrument | Mitutoyo Corporation | MF-J4020D | 400×200mm | 1 |

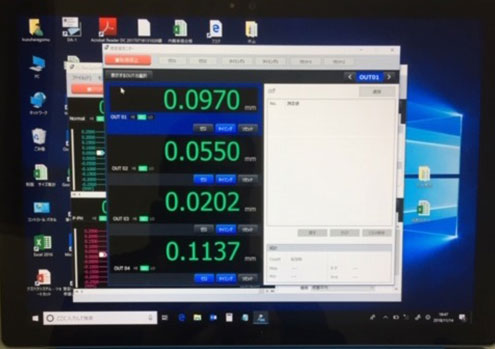

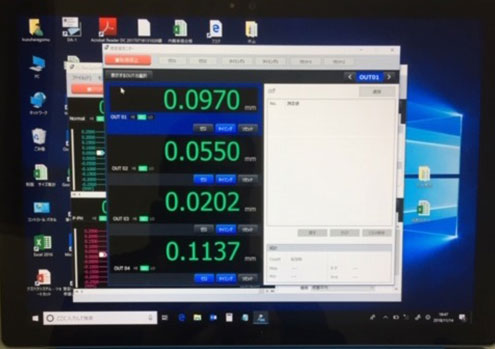

Flatness Inspection Machine

This machine, using an actuator installed, measures the height of the rotating work in use of a laser displacement meter. In order to enhance the quality of a rubber valve which is used under the environment where the valve is compressed by a low stress, we conduct a 100% in-line inspection by measuring the correlation between its flatness/height at the valve center and the height of its periphery. This gives the quality assurance of the rubber valve.

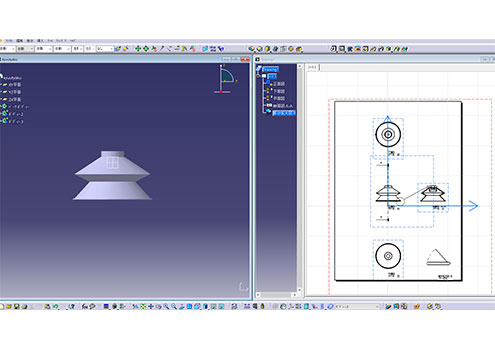

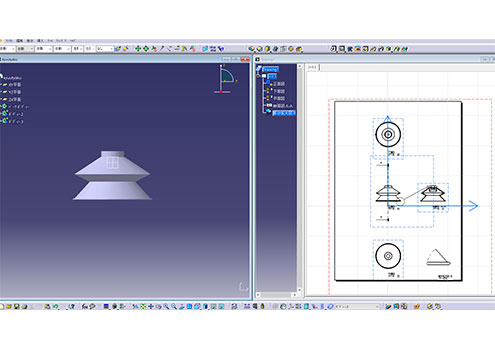

3D CAD (3-Dimensional Computer-Aided Design)

We use Mastercam CAD system and high-end 3D CAD CATIA V5 system which can handle from 2 axes to 5 axis composition and processing. These systems are widely used in such industry as automotive, aerospace, electric and industrial sectors. We accordingly can support you in a variety of industry from the design/development stage.

High precision image dimension measuring instrument

Our new measuring instrument allows anyone to simply use at high speed with high precision ±0.1μm . It also helps us to make quality assurance for production products requiring dimensional measurement. Its high speed measurement can shorten lead time of any samples off dies under development.

Wide Area 3-Dimensional Measuring Machine

(measuring instrument for large sized products)

This machine can handle measurement of large sized masking jigs and products. Quality verification prior to product shipment should help investigation of causes of any discrepancy at our customers and their corrective actions to be required in a speedy manner. The equipment can handle up to maximum length of 10 meters.

We can provide you with solutions to your rubber

molding and processing issues!