Management System for Quality Assurance

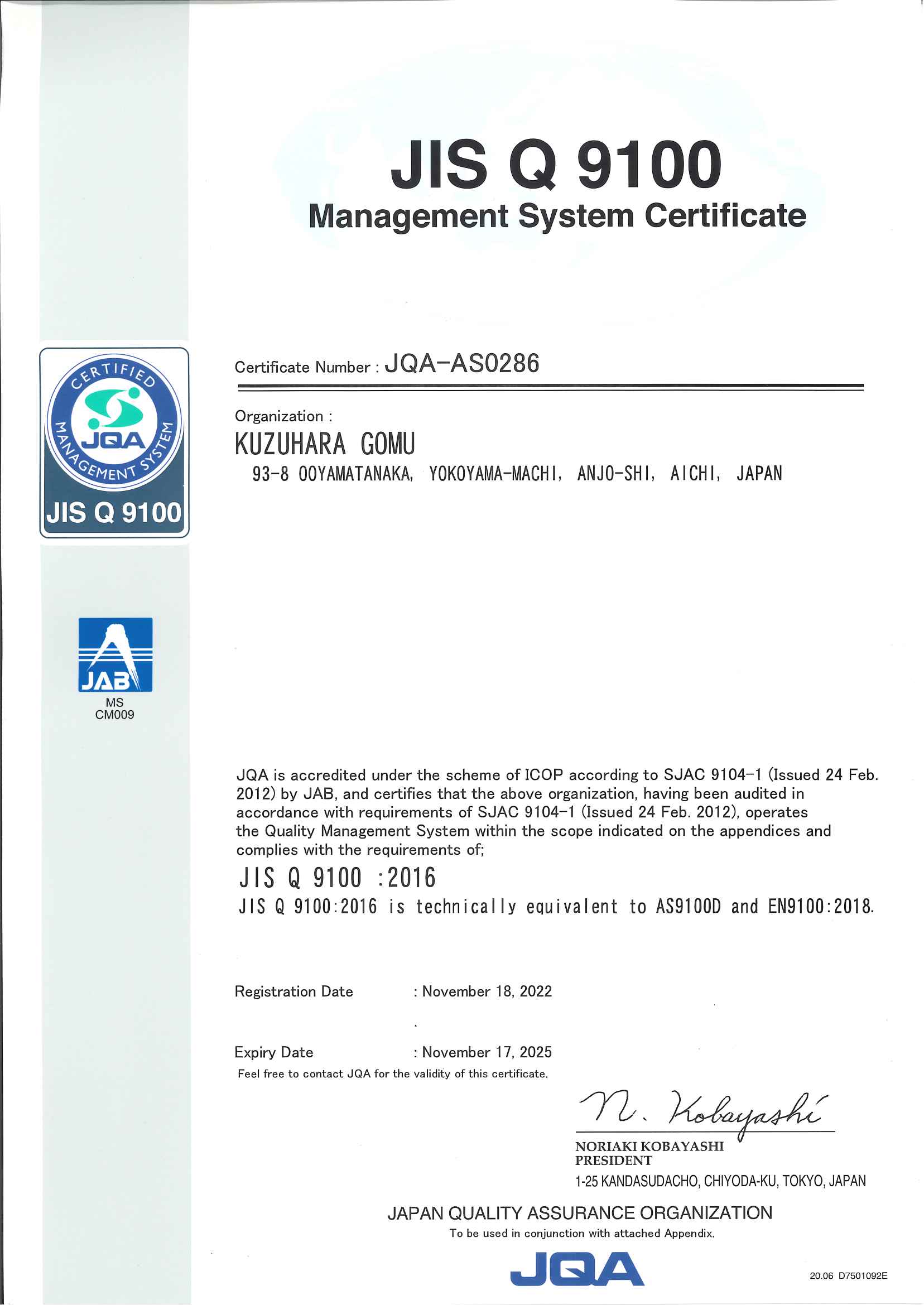

At Kuzuhara Gomu, we provide support for rubber molding and processing from the materials selection and design stage. With our ISO 9001 certification and stringent quality control, we continue to work on further enhancing quality assurance. All of our staff are united in their efforts to achieve zero defects, and work in accordance with our policy for ensuring quality. Please do not hesitate to contact us if there are any uncertainties or defects with any of our products; a staff member will address the issue immediately.

Kuzuhara Gomu Quality Policy

We recognize that compliance with laws, regulations, and other social norms is the minimum business code to follow. We are constantly improving our quality management system so that we can meet our customers’ expectations and needs, thereby achieving the following objectives.

1.Raise Customer Satisfaction

Achieve a higher on-time delivery rate and reduce "run-off" defective material.

2.Improve Work Efficiency

Carry out efficient and high-quality production plans and upgrade employees’ Quality of Life.

3.Increase Organizational Strength

Implement a quality policy that will accelerate the connection between employees, leading to a higher organizational strength.

4.Upgrade Technology

Utilize the quality management system and apply acquired technologies to enhance our technical capabilities.

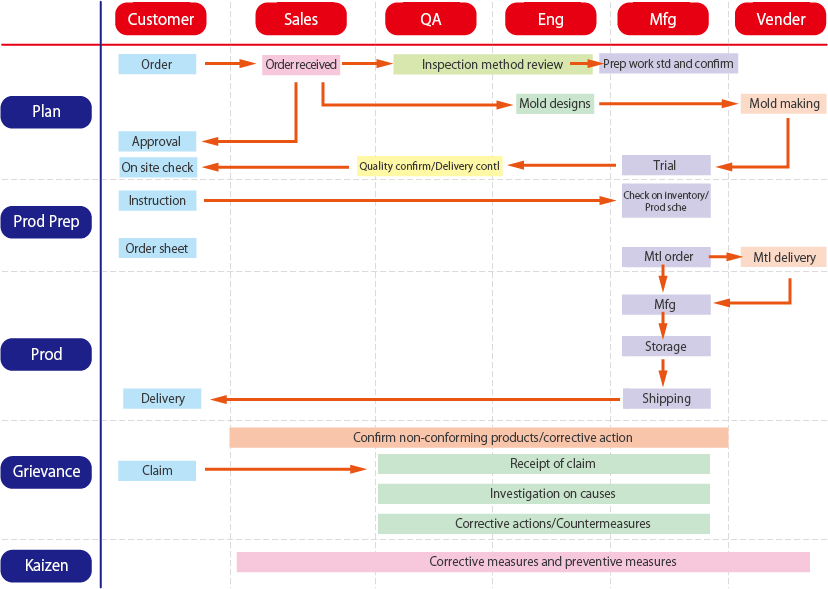

Quality Assurance System for Achieving Zero Defects

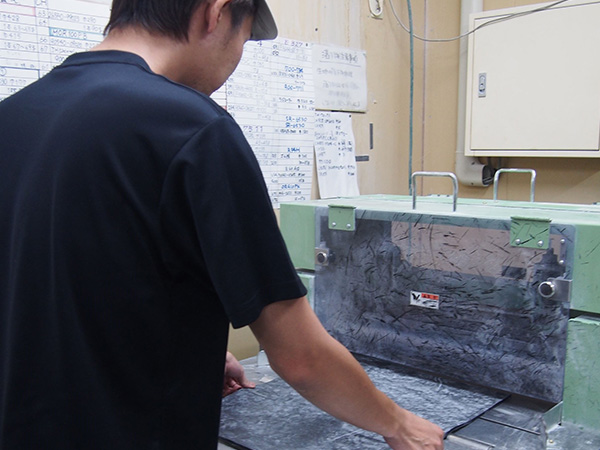

In order for us to secure a high quality of our products, we organize the quality assurance systems outlined in the diagram below. Our molds are so designed as to process the work within the given tolerances. The total inspection is undertaken on products depending on necessity, preventing non-conforming products from flowing out.

Thorough practice of the 5S’s and periodical machine maintenance

It is Kuzuhara Gomu’s philosophy that the thorough practice of the 5S’s (Seiri=Sort, Seiton=Set, Seiso=Shine, Seiketsu=Stabilize and Shitsuke=Sustain) can realize a high quality of products. We keep the 5S’s in mind for day to day operations, and each department appoints a person who is responsible for promoting the 5S’s in his/her workshop. We consider machine and equipment maintenance to be particularly important: besides daily Seiso or Shine, a periodical check on machine and equipment is followed up strictly. Such periodical check covers mold temperature, pressure capability of molding machines and molding duration. The check is done twice a day, at the opening and close of the work.

Safety Management and Safety Management Study Group Sessions

To prevent any industrial accident, Kuzuhara Gomu is working very hard on safety measures in the production plants and with machine and equipment. In addition to a periodical check on machines, material storages, passages, air conditioning equipment and others, we hold, on a periodical basis, a class on safety measures and a training session to share the safety related information.

Rubber Molding Processes

Here we will introduce the general processes for rubber molding.

STEP1Preparation and kneading of the rubber raw materials and agents

In this process, multiple agents are blended with the raw rubber material and such compound is kneaded by the machine, called rolling machine. In case of a pigment to be required, its requirements are added during this kneading process, and its color is also adjusted. This process determines strength, hardness and characteristics of the rubber itself.

STEP2Rubber cutting

The material kneaded thru the rolling machine is processed into the one with thickness fitting to respective products. The material in the form of sheet is cut into the size and the structure required for molding.

STEP3Molding

The molds are set on the press machine into which the cut rubber material is placed. Heat and pressure are added to the molds, hardening the clay-like rubber material, resulting in the designed configurations.

STEP4Finishing

Removed is a portion protruded from the mold, called “burrs” which is unnecessary to the finished product.

STEP5Visual inspection and Shipping

A visual inspection is done on the finished products and those passing inspection are shipped to customers.

We can provide you with solutions to your rubber

molding and processing issues!